Multifunctional winemaker

Industry 4.0 Ready

Wave multifunctional winemaker

Patented by GHIDI METALLI Srl, it is available from 20 to 150hl.

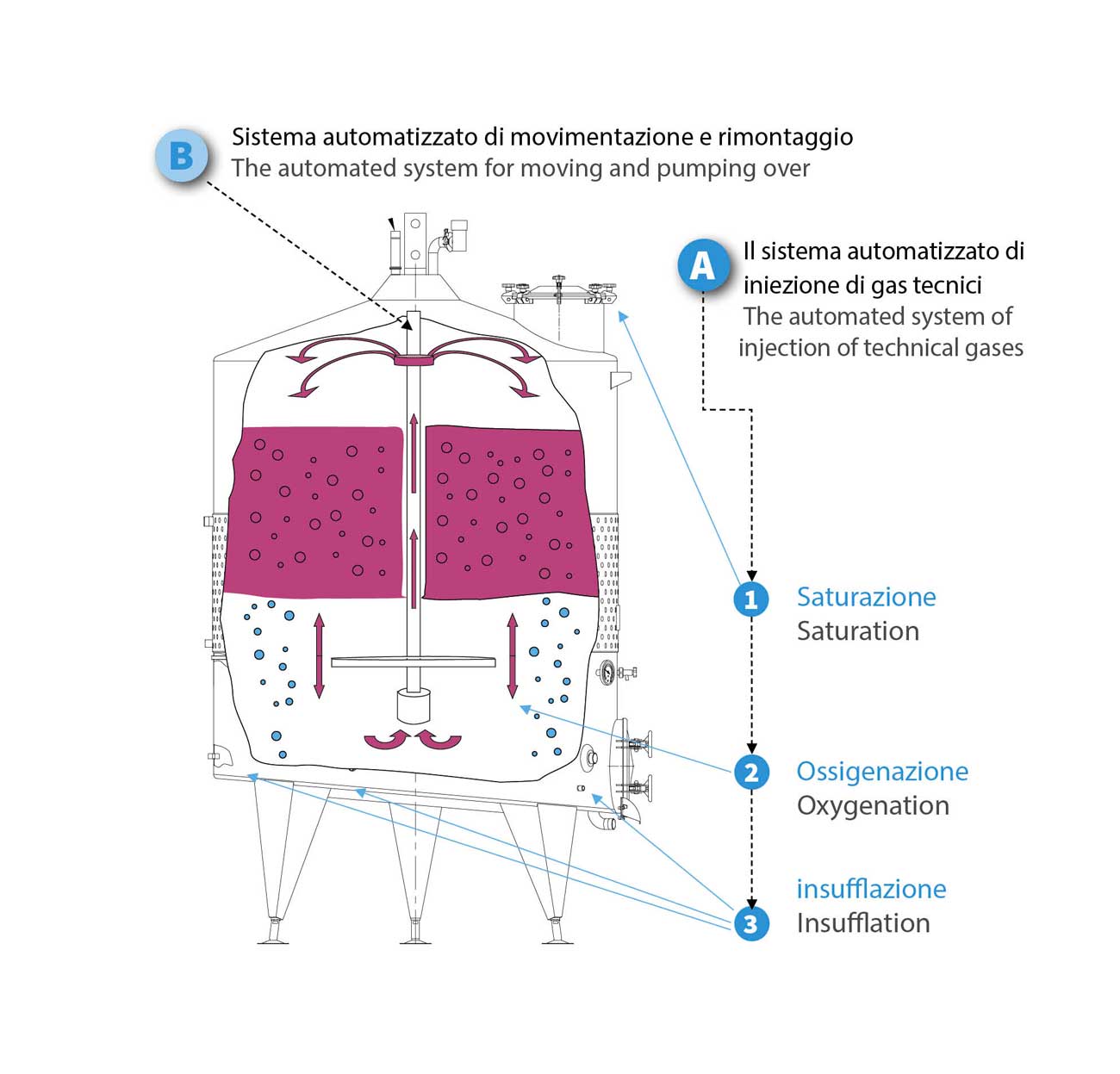

ONDA, the innovative winemaker patented by Ghidi Metalli, has an automated technical gas injection system in three specific zones of the winemaker that allows the regulation of the redox potential of the must or wine through precise and targeted interventions.

The new multifunctional winemaker Wave ®, is equipped with a PLC for automated control of winemaking processes and meets the requirements for funding called “industry 4.0” and “industry 5.0.”

new technology

The innovative

features

by Wave

A – The automated system of technical gas injection (compressed air, nitrogen, argon,CO2 or mixtures of these gases) into three specific zones of the tank. Saturation from above for aging and long-term storage in a protected atmosphere. Oxygenation in the middle zone thanks to the integrated porous candle. Insufflation from below: with inert gas to gently mix the must/wine or bring fine lees into suspension during aging, or with compressed air for macro-oxygenation of the product.

B -The automated system of must or wine handling and pumping over without the use of pumps maximizes phenolic extraction while reducing must stress and lees production.

A–Automated injection system of technical gases

The automated technical gas injection system (nitrogen, argon,CO2, compressed air, or mixtures) operates in three specific zones of the tank: from below, in the middle zone, and from above. All gases are delivered from food-grade cylinders directly connected to the tank’s control panel, which allows for selection of the desired technical gas, adjustment of its quantity with special flow meters, and scheduling of insufflation cycles over 24 hours.

The insufflation of gas from below is accomplished by a series of microperforated injectors placed near the bottom.

Selecting the administration of inert gas makes it possible, for example, to gently stir the must during fermentation or maceration to facilitate exchanges between the liquid and solid phases of the must/wine, or to bring fine lees into suspension during maturation, or to rapidly saturate the tank with inert gas to carry out racking in a protected atmosphere.

By insufflating compressed air, it is possible to macro-oxygenate the must or wine (at all stages of winemaking: pre-fermentation, fermentation and post-fermentation).

In the middle zone: there is a porous candle equipped with a removable extension that allowsoxygenation of the must during fermentation, maceration or in case of the appearance of reduced hints (its use is not expected in aging).

From above: allows the free space above the must/wine to be saturated with inert gas (nitrogen or argon) and exploit Onda® for other winemaking steps besides fermentation, such as maceration, fine lees aging, and long-term storage.

B-Automated system for handling and pumping over of the must

The automated must handling and repassing system consists of a pneumatic piston, which raises and lowers a slotted tube to which a disc and check valve are attached. The system acts on the cap of grape marc from both above and below: with each push of the piston, the liquid rises along the tube and exits through its upper slot, creating a light, steady rain that wets the cap of marc from above; at the same time, the disk, which is immersed in the liquid part of the must, creates a wave that invests the cap at the bottom. Although Onda® may look like a normal fuller its operation is completely different because, by not exerting a direct mechanical action on the cap of grape marc, it reduces the stress on the must and the production of lees.

Through the control panel it is possible to set the number and duration of work cycles throughout the day.

saturation

Saturation from above for aging and long-term storage in a protected atmosphere.

oxygenation

Oxygenation in the middle zone due to the integrated porous candle

insufflation

Insufflation from below: with inert gas to gently stir the must/wine or bring fine lees into suspension during aging, or with compressed air for macro-oxygenation of the product.

Innovative

Control Panel

An intuitive control panel will allow you to easily perform all operations and keep track of all stages of winemaking

You want more

information?

Our team will be available for any information you need

wave winemaker

the advantages

1

MULTI FUNCTIONS.

Onda® can be used for most types of wine and at all stages of the winemaking process: pre- and post-fermentation maceration, alcoholic and malolactic fermentation, aging on fine lees and long-term storage.

2

EFFECTIVE AND GENTLE EXTRACTION

the automated system of handling and pumping over acts above and below the pomace cap and not directly on it, this maximizes the extraction of phenolic components while reducing the production of lees.

3

VERSATILITY

easily adapts to current winemaking protocols and simplifies normally complex operations or problems: pumping over, oxygenations, stopping or slowing down fermentation, putting fine lees in suspension, correcting reduced hints, saturating the tank with inert gas, etc.

4

EASY CLEANING.

Onda® is free of cavities, and all internal components are equipped with a rapid disassembly and flushing system that reduces the time for racking, cleaning, and sanitizing the tank.

6

ABILITY TO REGULATE REDOX POTENTIAL THROUGH TARGETED INTERVENTIONS

5

SAVINGS

It greatly reduces labor costs because it operates without the aid of pumps and related piping that require specialized personnel both to operate and clean them.

Onda® is fully automated: a single operator, thanks to the intuitive control panel, can program and manage the entire winemaking, aging and storage process, even of several tanks at once.

advantage

POSSIBILITY TO WINE WITHOUT ADDED SULPHITES.

Thanks to the pump-less pumping system and the technical gas injection system, a modified and controlled atmosphere is obtained within Onda® that has enabled the production of wines without the addition of sulfites or other allergens on both an experimental and production scale*.

——-

* By employing Onda® and adopting appropriate hygiene measures, suitable oenological equipment and a specific protocol, it has been shown to be possible to make wine without the addition of sulfites and other allergens; however, it is recommended that the procedures be recommended and approved by an experienced oenologist who is responsible for the quality of the final product.

What they say about Wave:

I chose the Ghidi fermentation tank with the wave system because I like as a first thing the possibility of using less chemistry in the wines I produce, the thing I noticed right away from the first fermentation done in 2017 that the wine coming out of the tank has from the beginning a nice softness and great aromas that from a normal fermentation you don’t have.

I call it a more complete wine, and you can feel all that some very good grapes express.

During the phase of aging in wood that is coming to an end, it had a better reaction to wood while retaining all the initial characteristics and developed even more.

The aromas and elegance unlike the other wines in the cellar.

I am glad to have gone down this road, and in the next few years I will integrate more tanks with the wave system.

ASK FOR INFORMATION

If you need more information and quotes, our team is available for any request

awards

To the conquest

of innovation awards

to Simei

The Wave Winemaker, patented by Ghidi Metalli received“Special Mention” at the 2011 Simei“Innovation Award” and the “Innovation Challenge New Technology” Award at Simei 2015.

The purpose of the competition is to enhance and publicize the work by manufacturers of equipment, products and services that present product and process innovations that can predict technical progress in the field of oenology.

The entries were judged by national and international personalities from the world of oenology, representatives of the scientific community and leading wineries associated with Unione Italiana Vini.

SIMEI 2015

Innovation Challenge

New Technology 2015

SIMEI 2011

“Special Mention”

Innovation Award 2011

SCIENTIFIC RESULTS

WAVE WINEMAKER NEW TECHNOLOGY EXPERIMENTATION DIBAF

WAVE WINEMAKER – Enoforum 2011

WAVE WINEMAKER – DIBAF EXPERIMENTATION 2016

press review

December 2015 – La Vigne

LE SIMEI FACILITE LA TÂCHE DES VINIFICATEURS

September 17, 2015 – SIMEI – World leader in wine technology exhibition

INNOVATION CHALLENGE: COMMITTEE CHOOSES 21 INNOVATIVE PROJECTS

July 2015 – EXPO 2015 – TUSCANY REGION – The Excellent Companies.

TUSCANY OF BEAUTIFUL LIVING COMBINES AGRIBUSINESS WITH THE MOST INNOVATIVE TECHNOLOGICAL PRODUCTIONS

July 29, 2015 – PORTHOS – Independent for as long as we can remember, we’re all about wine, food and culture

SULFITE-FREE WINES – LEAVE IT TO NATURE

November 2012 – Award for viticultural and oenological innovation- Simei 2011

LIST OF AWARDEES

October 10, 2011 – The Wine Courier no. 40

ALL MERIT REPORTS

Blog

News & experiments

Environment and responsible production

Our stainless steel tanks are durable products designed for long-term use. Their use reduces the...

Accessing “industry 4.0” funding with the Wave Winemaker®

The new multifunctional winemaker Onda ®, is equipped with a PLC to control the winemaking process...

Automatic bâtonnage in Onda® tank.

AGING ON FINE LEES OF CHARDONNAY WINE WITH BÂAUTOMATIC TONNAGE IN ONDA® TANK Automatic bâtonnage...

Onda® Installation and Testing

WAVE WINEMAKER: NEW INSTALLATIONS We went to the province of Salerno to install and test, in a new...

6 Wave ready to go

Here are 6 carefully constructed Onda® Vinificators, off to places where they are sure to deliver...

A WINE WHERE THE GRAPES EXPRESS THEMSELVES TO THE FULLEST

We visited Gianni Bernazzi of Azienda Agricola Bellaria in Montalcino to see how the vinification...

WAVE WINEMAKER: IT IS ALSO PATENT IN THE UNITED STATES AND CANADA

The Onda multifunctional winemaker is confirmed as an innovative and unique product on the market:...

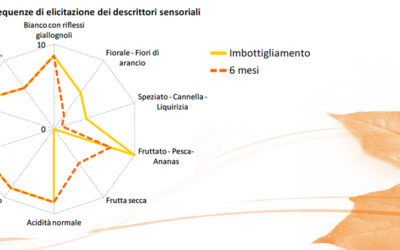

Vinifying Sangiovese by regulating the redox potential

The Onda® winemaker compared to a conventional winemaker to Vinify Sangiovese by adjusting the...

The experimental results of wines without added sulfites* produced with the Onda® Winemaker

Results of experimentation of wines without added sulfites* produced with the Wave Winemaker ®...

Vinified in the Wave!

Congratulations to Rossovermiglio company for the prestigious achievement Rossovermiglio winery's...

Scientific results (2016) on Onda®, the winemaker that enables the production of wines with low or no added sulfites

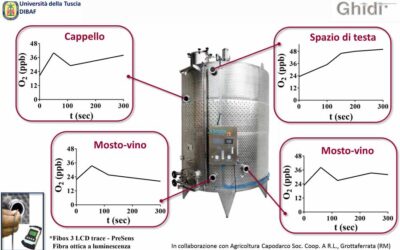

Experimentation conducted by DIPARTIMENTO PER LA INNOVAZIONE NEI IN SISTEMI BIOLOGICI...

The Wine Consolidation Act is now law and….

The Unified Wine Law is now law. A cut in red tape and more opportunities for producers. Ghidi...

Sulfites in wine and wine without added sulfites

Sulfites in wine and wine without added sulfites. The Onda® winemaker is a valuable tool...

Wave winemaker – 6 reasons to choose it

Wave Winemaker - 6 reasons to choose it. Vinification, aging and long-term storage The Onda...

Atmosphere controlled, wave winemaker study

The Wave winemaker and the stages of controlled atmosphere winemaking This is a study on the use...

Wine without added sulfites – using the Onda winemaker

Wine without added sulfites - Vermentino 2015 Wine without added soflites produced by the...

Wines & Vines

After winning the INNOVATION CHALLENGE NEW TECHNOLOGY - SIMEI ENOVITIS 2015 INNOVATION PRIZE, we...

New Technology Simei 2015 Award Ceremony

The 26th SIMEI International Enological and Bottling Machinery Exhibition ended on a positive note...