STAINLESS STEEL TANKS

Four generations

In the transformation of sheet metal

Production and sale of stainless steel tanks and containers

GHIDI METALS

FOUR GENERATIONS OF EXPERIENCE IN WELDING AND SHEET METAL FABRICATION

At the heart of any workmanship is, as always, a great deal of attention paid to the customer. For this reason, Ghidi Metalli offers the opportunity, To create customized projects for every need. Each project, made and approved by the customer, becomes reality through the use of state-of-the-art machines and equipment.

We design and manufacture high-quality stainless steel containers for processing and storage of: wine, oil, beer, honey, fruit juices, milk, liquors, herbal infusions, as well as liquids and solids for the food and pharmaceutical industries.

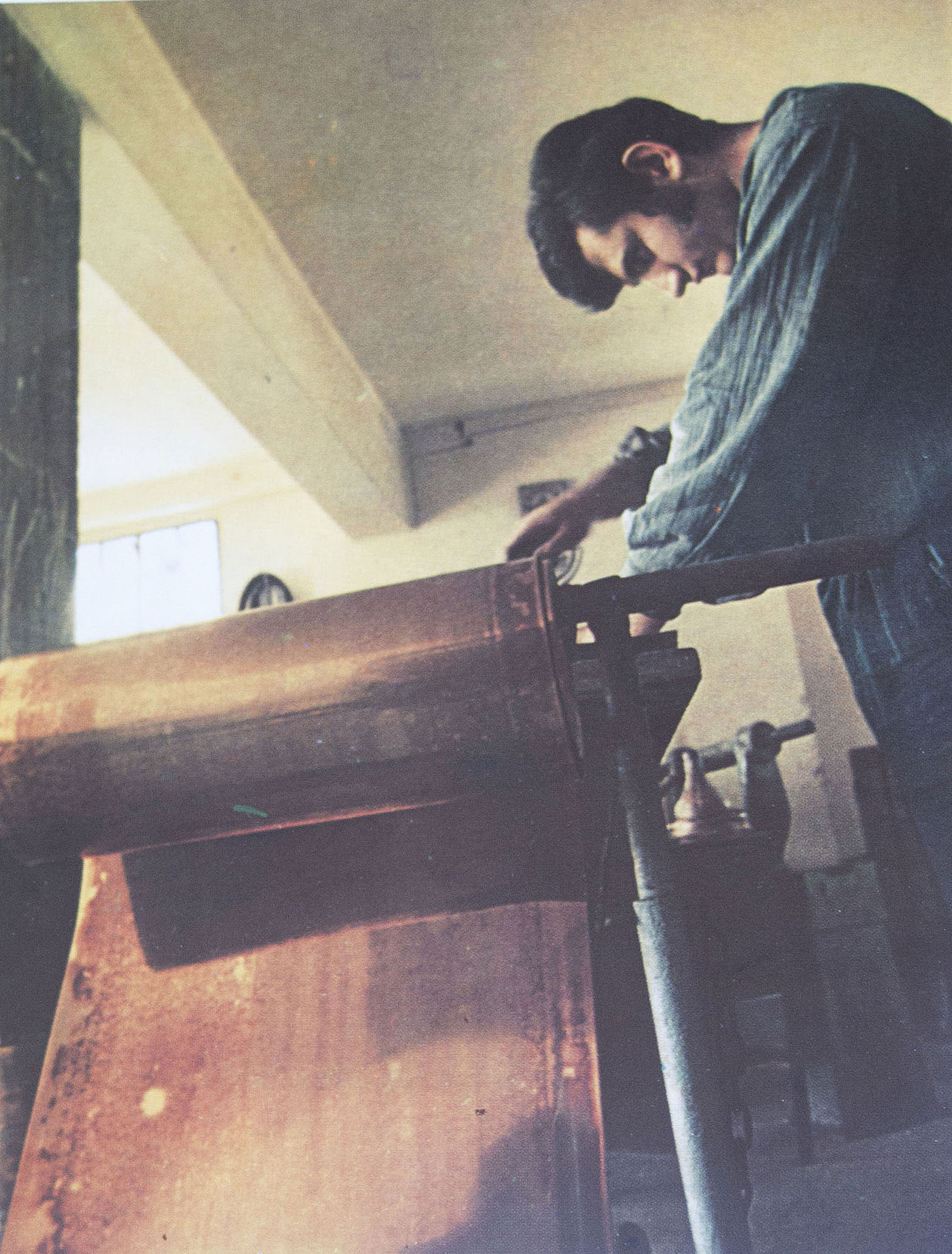

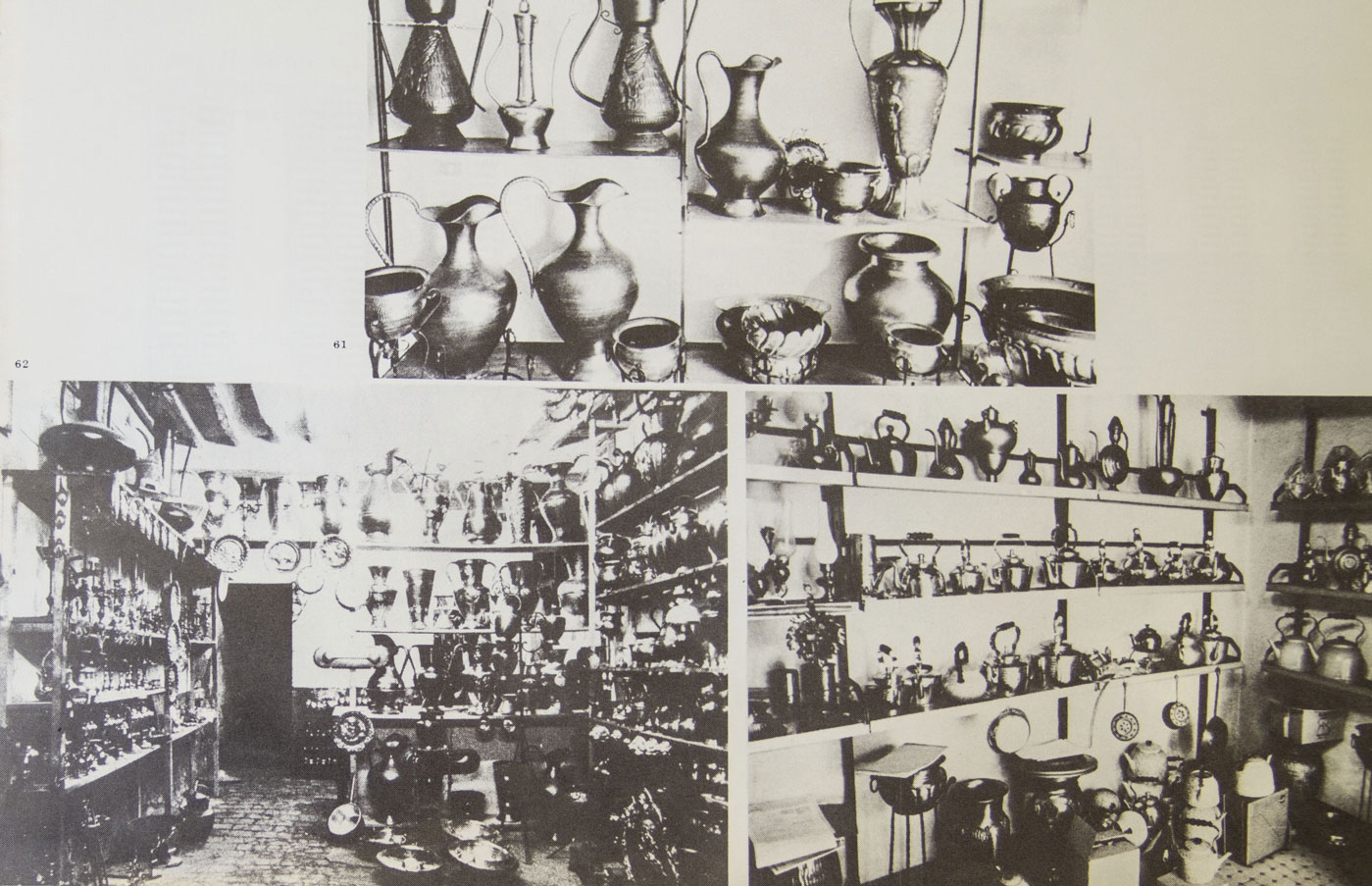

Ghidi Metalli was born the early 1900s, founded by Orfeo Ghidi. The first products were artistic objects made of copper and brass. As early as 1968 it won the Chamber of Commerce’s export award, which was given to the company for the many furniture items made of copper that were exported to the United States. The company then went on to establish itself in the production of stainless steel tanks. Today Ghidi Metalli, a manufacturer of stainless steel tanks, works with wineries, oil mills and many others in the food industry, with the goal of preserving the quality of the finest food liquids. Starting in the Valdinievole, Tuscany, today it serves customers all over the world thanks to innovative products of the highest quality: containers, tanks, winemakers, inert tanks with nitrogen or argon, customized tanks and much more.

Welcome to our Catalogs section

For four generations, we have been manufacturers of stainless tanks

Always operating in the sheet metal processing industry, the Ghidi family continues to hand down its skills from generation to generation: it all began with the sheet metal shop that, four generations ago, was opened by their grandfather and which, evolving and adapting to market demands, has carried its legacy to the present day, evidenced by the technical expertise found in the details of each individual process.

Today Ghidi Metals, stainless tank manufacturers, works alongside wineries and oil mills and beyond: preserving the quality of noble food liquids is the company’s mission. From the Valdinievole, Tuscany, to the world the step has been taken, but each new customer is an opportunity and desire for comparison, for improvements for our -Manufacturing of stainless steel tanks, wine makers, tanks and containers for wine, oil, honey, fruit juices, milk, liquors, herbal infusions, liquids and solids in general.

Technology & design

Design and fabrication of stainless steel tanks

WE DESIGN AND MANUFACTURE STAINLESS STEEL TANKS ACCORDING TO CUSTOMER REQUIREMENTS

Ghidi Metalli is able to design stainless steel tanks through state-of-the-art machine and equipment technology.

AISI 304 and 316 high-grade stainless steel sheet metal

Construction of high-grade and certified AISI 304 and 316 stainless steel sheet metal. Full discharge domed bottom with sump

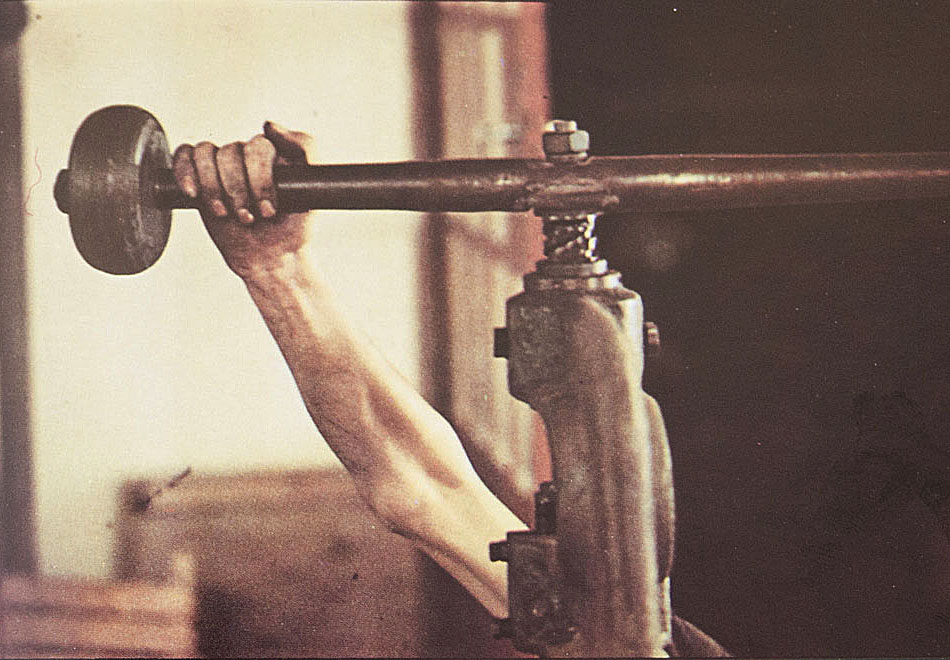

Digitally controlled TIG welding to ensure robustness and total reliability

Flowering: aesthetics and practicality

Molded front door Up to the capacity of 2000 liters front door cut out of the tank wall without welding

Specific design for each operating condition

All standard accessories in certified stainless steel (valves, level holders, sampling taps, etc.).

Pre-molded heat exchange band. Such construction technology ensures Superlative heat exchange efficiency. Saved by using less powerful chillers and on the cost of unnecessary insulation, avoided loss of exchange efficiency over time due to fouling inside the band.

Technology

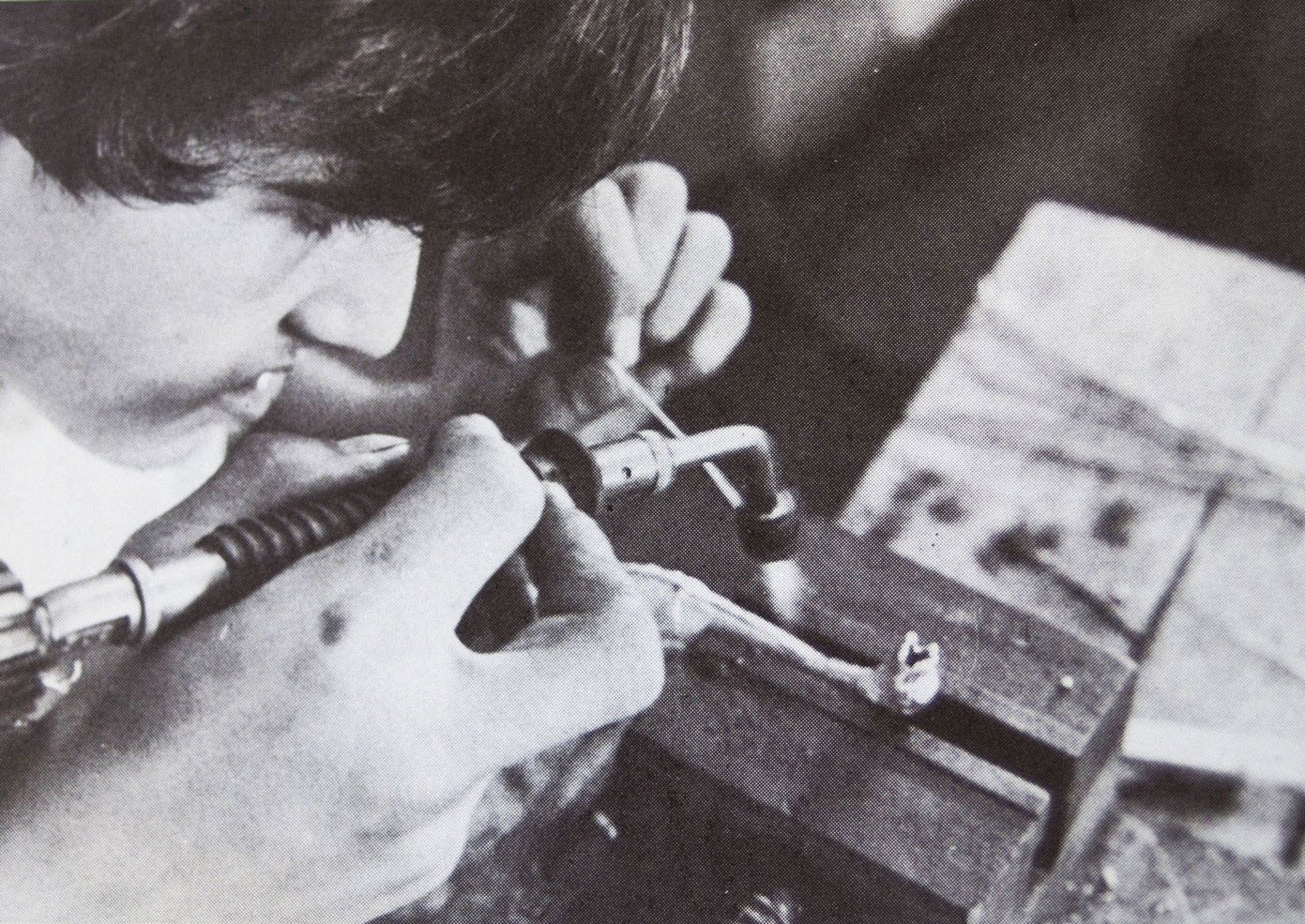

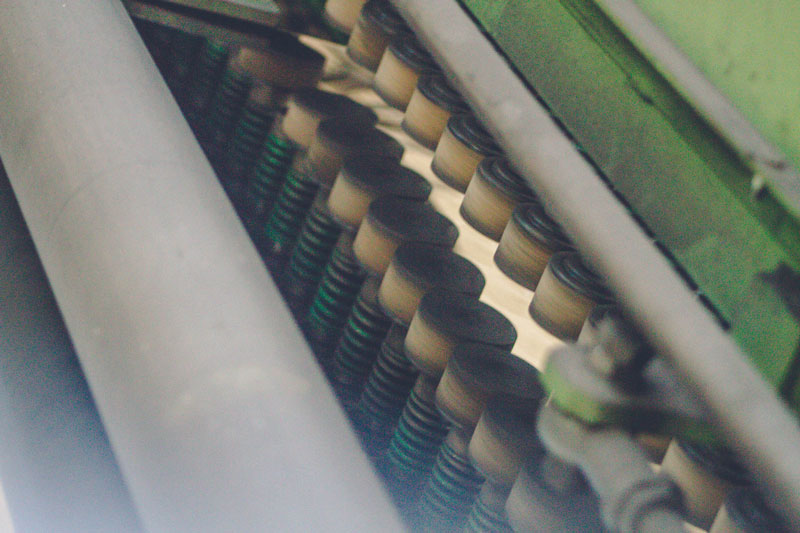

FLOWERING.

stainless steel

Flourishing is the first processing that is done on the stainless sheet metal and allows it to maintain a like-new appearance even after several years of use.

This particular exterior finish is achieved by grinding the sheet metal with staggered rotating pads with a constant 60° pitch. All of GhidiMetalli’s products have the external flocked finish included in the price, while inside the sheet remains polished for easy cleaning and hygiene.

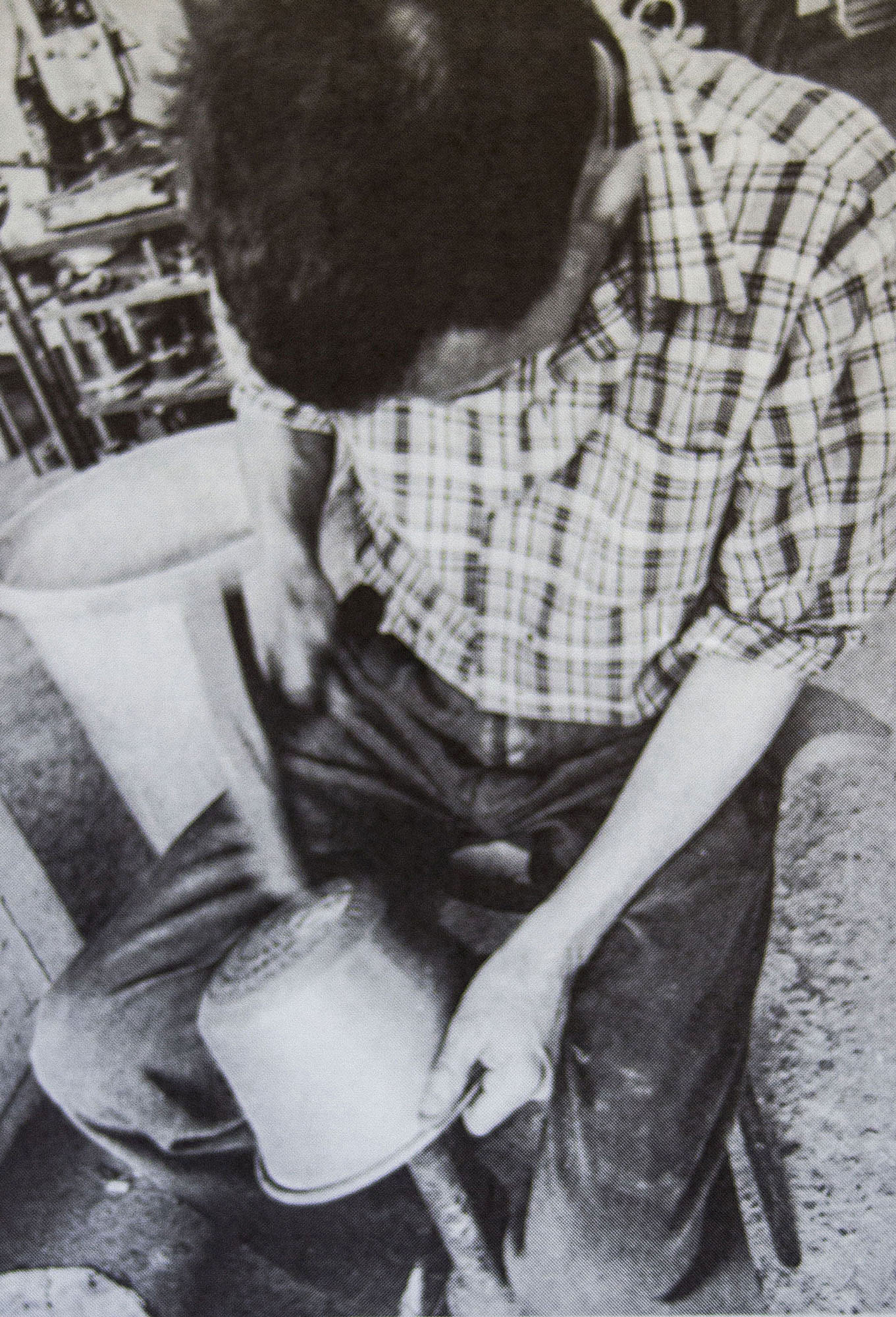

TIG WELDING

Tungsten inert gas

It is the California system that offers excellent technical and aesthetic guarantees, since it does not add material for thin and medium thicknesses, but limits the welding to the two edges to be joined by flashlight with tungsten electrode. The inert gas, fed into the welding phase, excludes oxygen, which is a cause of altering the molecular structure of steel and would make it attackable by liquids immersed in the container. For other sheet thicknesses, AISI 316 filler wire is also used. Constant digital control always ensures maximum weld accuracy.

Ghidi Metals | Stainless Steel Tanks and Containers

We offer value to our customers through continuous quality and innovation

Ghidi Metalli, four generations in the sheet metal processing industry. Using innovative technologies, we design and manufacture Stainless Steel Tanks according to customer requirements

Why choose Ghidi Metals:

AISI 304 and 316 stainless steel sheet

Specific design

TIG welding

Flowering

Printed front door

Integral one-piece construction

Preprinted heat exchange band

Get an accurate quote within 3-5 days by filling out this form. Or call us at: +39 0572 32216